1-4 DAYS DELIVERY

10.5T FLEDGE w- FAN + LV45 Rotor (Factory Installed) RED PURPLE BLACK [Acuvance] 60665 60666 60667

100% ORIGINAL AND QUALITY

24 MONTHS GUARANTEE

- Description

- Reviews

THESE ARE LIMITED EDITION

10.5T FLEDGE w/ FAN + LV45 Rotor (Factory Installed) RED PURPLE BLACK [Acuvance] 60665 60666 60667

SPECIAL EDITION (only a limited amount has been produced)

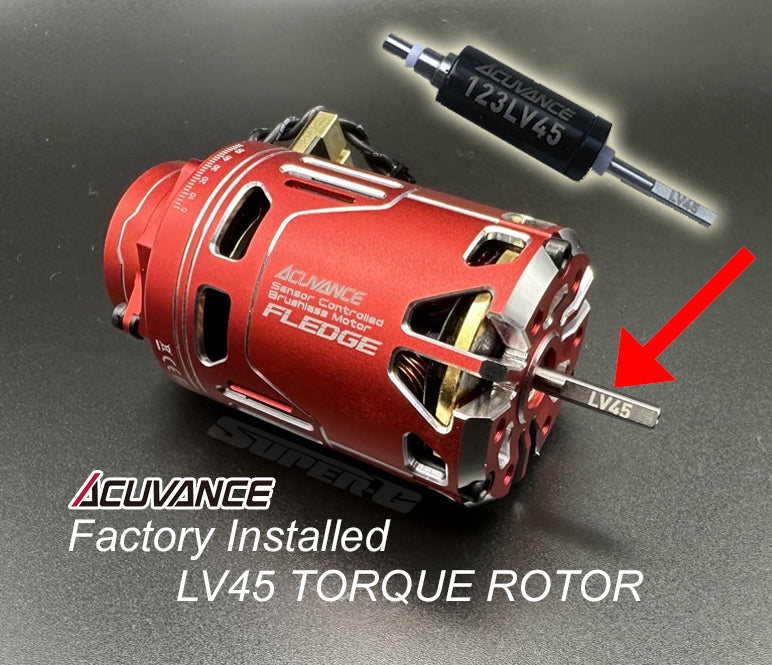

FLEDGE 10.5T w/ FAN + LV45 ROTOR (FACTORY INSTALLED)

*No need to purchase rotor and rotor tool extra.

You end up saving over $50-60 by not having to

purchase the rotor and tool separately. 100% ready to use!

FLEDGE

Next-generation brushless motor that combines high levels of torque, rotation, and efficiency with a revolutionary structural design like never before.

Equipped with the industry's first revolutionary system [A.V.S.] that realizes forced air cooling inside the motor.

Innovative structure that approaches direct cooling to the heat source by a dedicated FAN mounted on the end bell.

Air holes are located at various points inside the motor to maximize the air cooling effect.

It is very effective in reducing various negative factors due to heat generation of the motor, such as micro-misplacement of sensor signal, increase in coil resistance, and rotor damage.

Also, the dedicated FAN can be attached and detached according to the vehicle mounting space or driving environment.

In addition, our new brushless E.S.C. [XARVIS XX] has two dedicated FAN terminals.

Even when used in combination with the cooling fan for exclusive use of the XARVIS series [REY-Storm], the original air cooling performance is fully demonstrated.

[Vibration / Reduce] structure with high heat dissipation plate

Focusing on the internal vibration that affects the rotation efficiency generated when the motor is driven, a high-rigidity special alloy plate is mounted on the top side inside the housing.

A high quality design that makes use of a accurate and sharp body design by adding a porous structure proven in AGILE to a plate that boasts high heat dissipation characteristics.

[Direct power terminal system]

The power plate that connects the motor connector and coil has been integrated. (Industry first).

Vibration reduction and power transmission performance has been dramatically improved.

Not only the connector installation process is omitted, but also the solder contacts that become electrical resistance are eliminated.

Reduction of motor weight

While attention is being focused on reducing the weight of the chassis, a 12g weight reduction has been achieved while achieving a vibration-proof structure.

(Compared with our AGILE, when End bell fan is not installed)

Even when FAN is installed, the weight has been reduced by 6g.

Inherited the world's first [M.F.C.S.] used in AGILE as a RC motor

By changing only the magnetic force without changing the rotor diameter (volume and weight), it inherits the function [M.F.C.S] mounted on AGILE, which enables conversion to torque type and rotary type motors.

Even when replaced with an optional rotor, it achieves rotation and torque performance that is faithful to driver operation without compromising motor balance.

You can enjoy changes in output characteristics such as throttle feeling while taking advantage of the inherent performance of the motor.

Compatible with XARVIS XX FLEDGE / AGILE exclusive programs

Compatible with the program "torque level / torque end mode" installed in ACUVANCE brushless E.S.C.

It is a program exclusively for this product and AGILE users who can change the motor torque level according to the road surface and the chassis condition.

About motor size

Due to the structure of the FLEDGE, the distance from the motor mount contact surface to the terminal is shorter than the conventional motor by about 3 mm, so a motor mount spacer may be required depending on the chassis structure.

Please check the size below before purchasing.

Like the FLEDGE standard-equipped rotor, this is a high-power and high-speed black rotor exclusively for FLEDGE that uses neodymium magnets that boast the highest heat-resistant characteristics.

It is possible to change the rotation and torque characteristics of the motor without compromising the balance of weights and moments.

* This rotor is LV45, Torque type.

The smaller the LV value, the more the motor characteristics change to the rotary type, and the larger the LV value, the more the torque type. The standard rotor is LV38.