1-4 DAYS DELIVERY

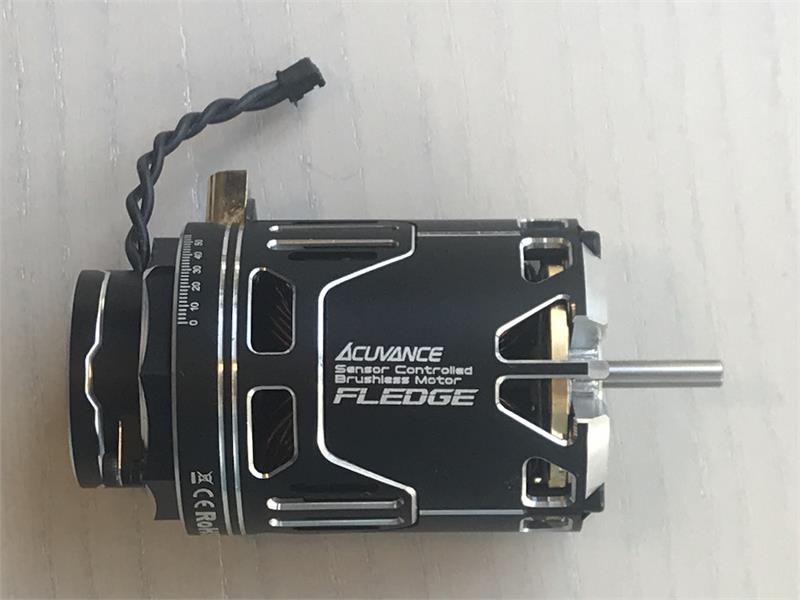

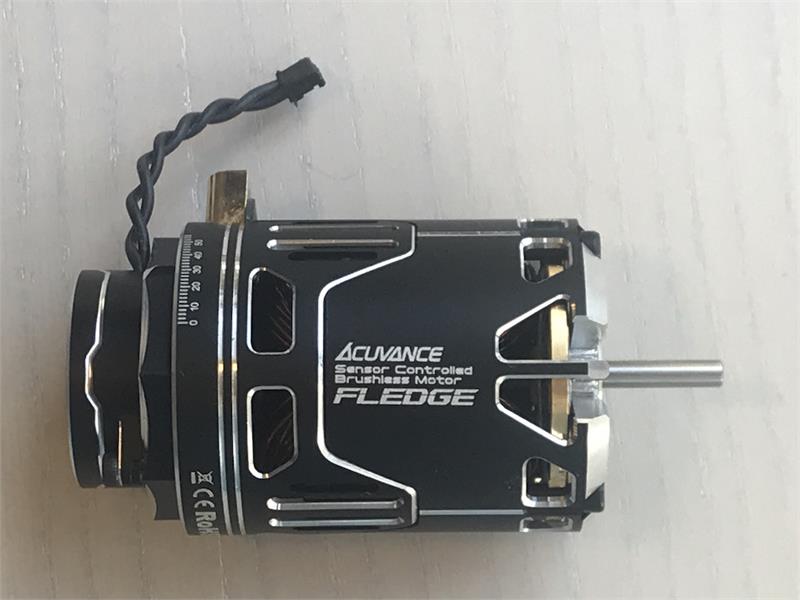

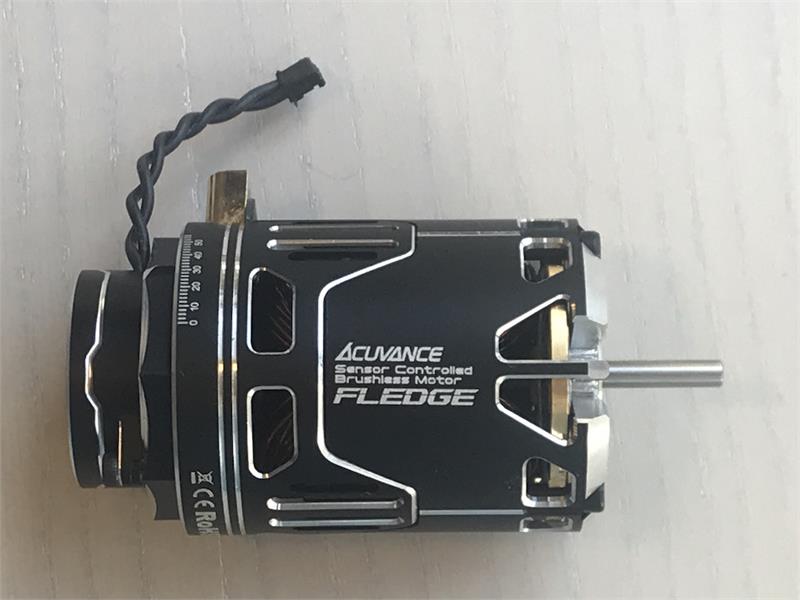

FLEDGE Forced Air-Cooled Brushless Motor for 1-10 RC CAR - 13.5T 10.5T 15.5T- Produced By ACUVANCE Japan

100% ORIGINAL AND QUALITY

24 MONTHS GUARANTEE

- Description

- ● Equipped with [AVS], the industry's first revolutionary system that realizes forced air cooling inside the motor

- ● Vibration-reducing structure with high heat dissipation plate

- ● Equipped with [Direct Power Terminal System]

- ● Uses neodymium magnets that boast the highest heat resistance in their class

- ● Reduce motor weight

- ● Inherits the world's first RC motor [MFCS] adopted in AGILE

- Reviews

FLEDGE

A next-generation brushless motor

with a high level of torque, rotation, and efficiency thanks to an unprecedented structural design.

● Equipped with [AVS], the industry's first revolutionary system that realizes forced air cooling inside the motorA revolutionary structure that uses a dedicated fan mounted on the end bell to provide direct cooling to the heat source. In addition, the dedicated fan can be freely attached or detached depending on the vehicle installation space and driving environment. ● Vibration-reducing structure with high heat dissipation plateWe focused on the internal vibrations that occur when the motor is in operation and that affect rotation efficiency. ● Equipped with [Direct Power Terminal System]The power plate that connects the motor connector and coil has been integrated (an industry first). This not ● Uses neodymium magnets that boast the highest heat resistance in their classUses a neodymium magnet with the highest class of heat resistance. ● Reduce motor weightWith the focus on making the machine lighter, this model has achieved a significant weight reduction of 12g (compared to our AGILE model, without the end bell fan) while still achieving an anti-vibration structure. ● Inherits the world's first RC motor [MFCS] adopted in AGILEInheriting the AGILE-exclusive [MFCS] that allows you to change only the magnetic force without changing the rotor diameter (volume and weight) and convert to a torque type or rotary motor. LINE UPProduct line-up

[Optional parts sold separately]

GEAR RATIO

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

10.5T |

13.5T |

|

|---|---|---|

| On-road technical course [7.2-7.4V] | 5.0:1 | 4.4:1 |

| On-road technical course [6.0V] | 5.2:1 | 4.6:1 |

| Off-road 2WD | 8.5:1 | 7.4:1 |

| Off-road 4WD | 7.8:1 | 6.5:1 |

| Off-road truck | 6.7:1 | 5.5:1 |

SPEC

Specifications

|

10.5T |

13.5T |

|

|---|---|---|

| Input voltage (V) | 4.8 - 11.1V | |

| KV (rpm/V)* | 3900 | 3030 |

| Power consumption (W)* | 250 | 190 |

| efficiency(%)※ | 92 | 92 |

| Standard rotor | Sintered φ12.3mm (Neodymium magnet) LV38 | |

| Coil winding method | Star Winding | |

*7.2V input, default lead angle 35°.

All values are at the factory.

SIZE

Motor size

Due to the structure of the FLEDGE, the distance from the motor mount contact surface to the terminal is approximately 3 mm shorter than that of conventional motors, so

a motor mount spacer may be required depending on the structure of the chassis.

Please check the sizes below before purchasing.

A revolutionary structure that uses a dedicated fan mounted on the end bell to provide direct cooling to the heat source.

Air holes are designed in various places inside the motor to maximize the cooling effect. This

is highly effective in reducing various negative factors caused by heat generated by the motor (such as extremely small misdirection of sensor signals, increased resistance in the coil section, and rotor damage).

In addition, the dedicated fan can be freely attached or detached depending on the vehicle installation space and driving environment.

Furthermore, our new brushless ESC [ XARVIS XX (Jarvis Double X) ] is equipped with two dedicated fan terminals. Even when used in conjunction with

the XARVIS series dedicated cooling fan [ REY-Storm ], it fully demonstrates its original air cooling performance.

We focused on the internal vibrations that occur when the motor is in operation and that affect rotation efficiency.

A highly rigid special alloy plate is installed on the top side of the inside of the housing. The porous structure proven in AGILE

is added to the plate, which boasts high heat dissipation properties , and it also serves as a high-quality accent that makes the most of the bold and sharp body design.

The power plate that connects the motor connector and coil has been integrated (an industry first). This not

only reduces vibration, but also dramatically improves power transmission performance. It

also eliminates the need for connector installation work, as well as the need for solder contacts that cause electrical resistance.

Uses a neodymium magnet with the highest class of heat resistance.

Combined with the aforementioned AVS and a plate with high heat dissipation properties, the heat resistance of the entire motor has been greatly improved.

With the focus on making the machine lighter, this model has achieved a significant weight reduction of 12g (compared to our AGILE model, without the end bell fan) while still achieving an anti-vibration structure.

Even with the fan installed, it is still 6g lighter.

Inheriting the AGILE-exclusive [MFCS] that allows you to change only the magnetic force without changing the rotor diameter (volume and weight) and convert to a torque type or rotary motor.

Even when replacing with an optional rotor (to be released at a later date), we have achieved rotation and torque performance that is faithful to the driver's operation without compromising the motor balance, so

you can enjoy changes in output characteristics such as throttle feeling while taking advantage of the original motor performance.

LINE UPProduct line-up

|

FLEDGE series lineup |

||||||

|---|---|---|---|---|---|---|

| Number of turns | Fan installed | FAN not installed | ||||

| black | Red | purple | black | Red | purple | |

| 10.5T | ○ | ○ | ○ | ○ | ○ | ○ |

| 13.5T | ○ | – | – | ○ | – | – |

| ¥22,000 + tax | ¥19,000 + tax | |||||

[Optional parts sold separately]

-

● Extension cable for FAN power supply [100mm, 150mm (¥600+tax each), 250mm (¥800+tax)]

*A 200mm power extension cable for the FAN is included with models equipped with the FLEDGE FAN. -

● Two-pronged cable for FAN power branching (¥800 + tax)

*When using in combination with XARVIS and FLEDGE, using the two-pronged cable will enable simultaneous connection of a FLEDGE-equipped FAN and our cooling FAN (REY-Storm, etc.). -

● Cooling fan set for FLEDGE [FAN, fan cover, special end bell, 200mm extension cable set] (¥5,000 + tax)

-

● End bell for when fan is not installed (¥1,200 + tax)

-

● High power/high speed black rotor (¥5,000 + tax)

-

● Lightweight motor mount spacer [3mm] (¥1,800 + tax)

-

● FAN connector-RX connector conversion cable (650 yen + tax)

*This cable converts the power connector of our FANs (including FLEDGE-equipped FANs) such as REY-Storm to an RX connector and supplies power from the receiver.

(This is an optional part for users who use it in combination with ESCs made by other companies.)

GEAR RATIO

Gear ratio reference value

GEAR RATIO

We have listed reference gear ratios for each category.

However, these are only reference values, and the optimal gear ratio will vary depending on the ESC performance, machine settings, course characteristics, etc., so please check the heat generation of the ESC and motor to determine the gear ratio that suits your driving style.

In addition, for the drift category, we have omitted it here because there are many factors that affect the appropriate gear ratio value, such as road grip conditions, driving style, and boost/turbo values. If you are using the drift category for the first time, please first refer to the "Off-road 2WD" values below and determine the gear ratio while checking the heat generation of the ESC and motor during about 5 to 10 minutes of driving.

|

10.5T |

13.5T |

|

|---|---|---|

| On-road technical course [7.2-7.4V] | 5.0:1 | 4.4:1 |

| On-road technical course [6.0V] | 5.2:1 | 4.6:1 |

| Off-road 2WD | 8.5:1 | 7.4:1 |

| Off-road 4WD | 7.8:1 | 6.5:1 |

| Off-road truck | 6.7:1 | 5.5:1 |

SPEC

Specifications

|

10.5T |

13.5T |

|

|---|---|---|

| Input voltage (V) | 4.8 - 11.1V | |

| KV (rpm/V)* | 3900 | 3030 |

| Power consumption (W)* | 250 | 190 |

| efficiency(%)※ | 92 | 92 |

| Standard rotor | Sintered φ12.3mm (Neodymium magnet) LV38 | |

| Coil winding method | Star Winding | |

*7.2V input, default lead angle 35°.

All values are at the factory.

SIZE

Motor size

Due to the structure of the FLEDGE, the distance from the motor mount contact surface to the terminal is approximately 3 mm shorter than that of conventional motors, so

a motor mount spacer may be required depending on the structure of the chassis.

Please check the sizes below before purchasing.

![Nissan Skyline HT2000 KPGC10 GT-R Hakosuka w Fender Flares 1-10 Body Set [ABC Hobby] 67093](http://supergdrift.com/cdn/shop/files/abc-hobby-nissan-skyline-ht2000-gt-r-kpgc10-hakosu_{width}x.webp?v=1769736716)

![XBONE 1-28 - SHOULDERED PIVOT BALL 6MM FOR XB-F1 [Xbility RC] X-PVB-6F](http://supergdrift.com/cdn/shop/files/X-PVB-4_369693e8-c6d0-4a95-98dc-e0b639aaaf53_{width}x.jpg?v=1769663447)

![MKS Super Metallic Chrome Markers (3 Colors) Detailing Hobby Model Paint Markers [DSPIAE] MKS Series](http://supergdrift.com/cdn/shop/files/MKS-main_5_{width}x.webp?v=1769660476)

![Intelligent DUAL (2 port) LiPo/LiHV/LiFe AC/DC Charger (6S/16A) (AC-300W) (DC-350W x2) [EcoPower] ECP-1016](http://supergdrift.com/cdn/shop/files/ecp-1016_{width}x.webp?v=1769660167)

![Izusu Bellett Fastback GT-R 196mm 1-10 Body Set [Pandora] PAB-3143](http://supergdrift.com/cdn/shop/files/BELLETT-3_{width}x.jpg?v=1769659909)

![Spoiler for 1-10 Nissan Fairlady Z33 350Z Spirit Rei HB14 [Addiction] AD-HB14W](http://supergdrift.com/cdn/shop/files/hb14w_{width}x.jpg?v=1769659584)

![Nissan Sunny Sedan B110 195mm 1-10 Body Set [Pandora] PAB-3144](http://supergdrift.com/cdn/shop/files/B110-1_{width}x.jpg?v=1769658922)