1-4 DAYS DELIVERY

Acuvance

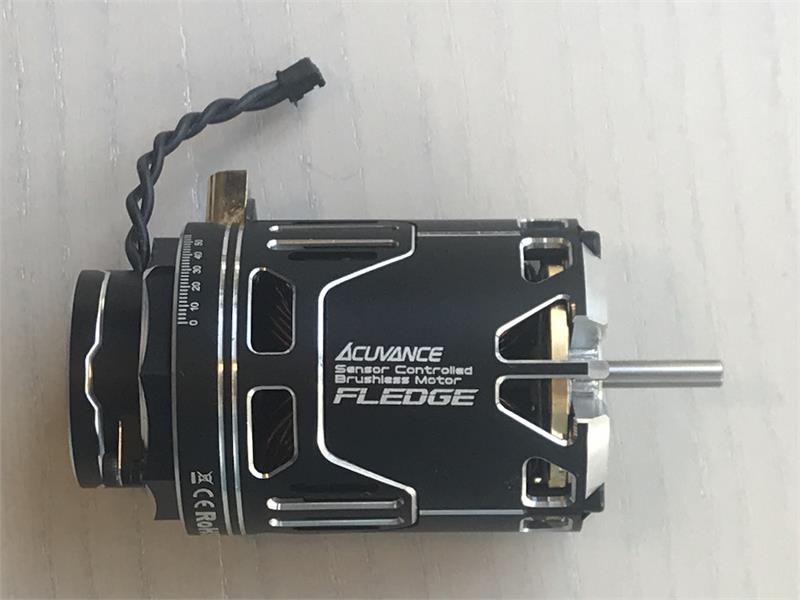

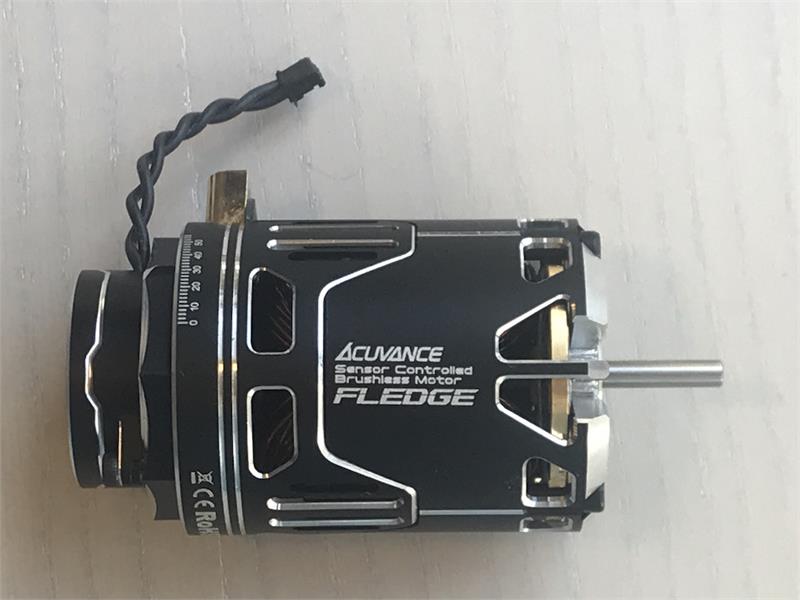

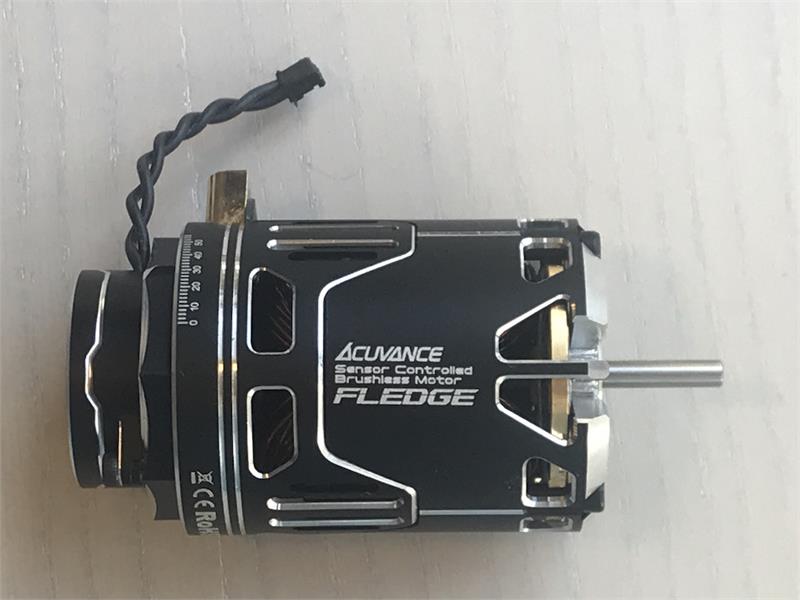

FLEDGE Forced Air-Cooled Brushless Motor for 1-10 RC CAR - 13.5T 10.5T 15.5T- Produced By ACUVANCE Japan

$179.99

In Stock

Pre-Order

Sold out

SKU: 60655 (Black)

SKU: 60655 (Black)

Categories: All Products, Electronics, Motors

100% ORIGINAL AND QUALITY

24 MONTHS GUARANTEE

- Description

- ● Equipped with [AVS], the industry's first revolutionary system that realizes forced air cooling inside the motor.

- ● [Vibration Reduce] structure equipped with a plate with high heat dissipation properties

- ● Equipped with [Direct Power Terminal System]

- ● Adopts a neodymium magnet that boasts the highest heat resistance properties in its class.

- ● Reduced motor weight

- ● AGILE inherits the world's first MFCS as an RC motor.

- ● Compatible with XARVIS XX FLEDGE/AGILE dedicated program

- [About handling of aluminum case products]

- Reviews

FLEDGE

_

A next-generation brushless motor

with a high level of torque, rotation, and efficiency thanks to an unprecedented structural design.

|

FLEDGE series lineup

|

||||||

|---|---|---|---|---|---|---|

| number of turns | Equipped with FAN | Not equipped with FAN | ||||

| black | red | purple | black | red | purple | |

| 10.5T | ○ | ○ | ○ | ○ | ○ | ○ |

| 13.5T | ○ | – | – | ○ | – | – |

FeaturesFEATURES An innovative structure that approaches [direct cooling to the heat source] using a dedicated FAN installed in the end bell. Air holes are designed at various locations inside the motor to maximize the air cooling effect. It is highly effective in reducing various negative factors caused by motor heat generation (minimum sensor signal delay, increase in coil resistance, rotor damage, etc.). In addition, the dedicated fan can be attached or detached to suit the vehicle mounting space and driving environment. Furthermore, our new brushless ESC [ XARVIS XX] is equipped with two FAN-dedicated terminals. Even when used with the XARVIS series dedicated cooling fan [ REY-Storm ], it fully demonstrates its original air cooling performance. We focused on internal vibrations that occur when driving a motor and also affect rotational efficiency. A highly rigid special alloy plate is mounted on the top side inside the housing. AGILE 's well-proven porous structure is added to the plate that boasts high heat dissipation properties , creating a high-quality accent that makes use of the fearless and sharp body design. The power plate that connects the motor connector and the coil has an integrated structure (an industry first). In addition to reducing vibration, power transmission performance has been dramatically improved. In addition to omitting the connector installation process, we also eliminate solder contacts that cause electrical resistance. Adopts a neodymium magnet with the highest heat resistance. Combined with the aforementioned [AVS] and high heat dissipation characteristic plate, the heat resistance of the entire motor has been significantly strengthened. As attention is focused on reducing the weight of machines, we have achieved a significant weight reduction of 12g (compared to our AGILE, without Endbell FAN) while achieving a vibration-proof structure. Even when a fan is installed, a weight reduction of 6g has been achieved. Inheriting AGILE's [MFCS], which allows only the magnetic force to be changed without changing the rotor diameter (volume/weight) and allows conversion to a torque type/rotary type motor. Even when replacing with the optional rotor (scheduled for release at a later date), we have achieved rotation and torque performance that is faithful to the driver's operation without compromising the motor balance.While taking advantage of the original performance of the motor, we are able to accommodate changes in output characteristics such as throttle feeling . You can enjoy it. Compatible with the program "Torque Level/Torque End Mode" installed in our brushless ESC [XARVIS XX]. This is a program exclusively for this product and AGILE users that allows you to vary the motor torque level depending on the road surface condition and vehicle. |

[Optional parts sold separately]

GEAR RATIOreference valueGEAR RATIO Reference gear ratios for each category are listed. However, these values are for reference only, and the optimal gear ratio will vary depending on the performance of the ESC, machine settings, course characteristics, etc., so check the amount of heat generated by the ESC and motor and choose the gear ratio that suits your driving style. Please decide. In addition, the drift category is omitted here because there are many factors that affect the appropriate gear ratio value, such as road grip conditions, driving style, boost/turbo values, etc. If this is your first time using the drift category, please first refer to the "Off-road 2WD" values below and determine the gear ratio while checking the heat generation of the ESC and motor during driving for about 5 to 10 minutes. please.

SpecificationsSPEC

* At 7.2V input and default lead angle of 35°, all values are in the shipping state. Motor SizeSIZE Due to the structure of FLEDGE, the distance from the motor mount contact surface to the terminal is about 3 mm shorter than conventional motors, so a motor mount spacer may be required depending on the chassis structure. Please check the size below before purchasing.

OTHERothersOTHER Products with aluminum cases may have sharp edges due to the cutting process, so please handle with care when installing the product in a vehicle or changing the layout. |

|||||||||||||||||||||||||||||||||||||||

![BRASS Weighted M3 Spacer Shims (3mm 5mm 7mm 10mm) (8-Pack) [Scale Reflex] 830043](http://supergdrift.com/cdn/shop/files/IMG_6019_{width}x.jpg?v=1715565610)

![1/24 RTS - TC4 Titanium Steering Rack Upgrade [Rhino Racing] RTS-608](http://supergdrift.com/cdn/shop/files/RTS-608Large_{width}x.jpg?v=1715472516)

![1/24 RTS - TC4 Titanium Body Mount Upgrade [Rhino Racing] RTS-607](http://supergdrift.com/cdn/shop/files/RTS-607Large_{width}x.jpg?v=1715472443)

![1/24 RTS - TC4 Titanium Arm Mount Set Upgrade [Rhino Racing] RTS-606](http://supergdrift.com/cdn/shop/files/RTS-606Large_{width}x.jpg?v=1715472387)

![1/24 RTS - RTS - TC4 Titanium Upper Arms Set Upgrade [Rhino Racing] RTS-605](http://supergdrift.com/cdn/shop/files/RTS-605Large_{width}x.jpg?v=1715472293)

![1/24 RTS - TC4 Titanium Servo Lower Mount Upgrade [Rhino Racing] RTS-604](http://supergdrift.com/cdn/shop/files/RTS-604Large_{width}x.jpg?v=1715472206)

![1/24 RTS - TC4 Titanium Lower Arms Set Upgrade [Rhino Racing] RTS-600](http://supergdrift.com/cdn/shop/files/RTS-600Large_{width}x.jpg?v=1715472109)

![GRAN SEEKER (mesh) ALUMI SILVER FACE DISC for Super-Rim (2 pc) [Tetsujin] TT-7121](http://supergdrift.com/cdn/shop/files/63cb9d503247d22239d4284c397139c2_{width}x.jpg?v=1715325171)

![GRAN SEEKER (mesh) GUN METAL FACE DISC for Super-Rim (2 pc) [Tetsujin] TT-7149](http://supergdrift.com/cdn/shop/files/1e0432622d93059e0177b0a738bed3a1_{width}x.jpg?v=1715325083)

![LYCORIS (mesh) Metallic RED FACE DISC for Super-Rim (2 pc) [Tetsujin] TT-8023](http://supergdrift.com/cdn/shop/files/unnamed__13278_{width}x.jpg?v=1715324905)